Protecting the precious environment

Biodiversity

Our business activities are built upon the rich natural environment. We will endeavor to prevent pollution and give consideration to nature and ecosystem and contribute to restoring them.

Haseko Group Code of Conduct on Biodiversity

Basic philosophy

The Haseko Group engages in corporate activities based on its Group Philosophy “To contribute to society by creating an optimal environment for cities and people.” By engaging in biodiversity-conscious corporate activities based on the recognition that people and companies reap various benefits from the natural environment, we will endeavor to help conserve and improve biodiversity in pursuit of a more comfortable and sustainable global environment.

Action guidelines

- Compliance

We will comply with laws and regulations, etc. related to biodiversity conservation, identify related policies and social demands and endeavor to reflect our knowledge of them in business activities. - Education and enlightenment

We will spread knowledge required for biodiversity conservation activities and information on laws and regulations, etc. through in-house education, etc. and raise employees’ awareness of the value of the ecosystem. - Consideration in construction business

We will implement biodiversity-conscious plans, designs and proposals, and endeavor to avert and reduce the impact of construction work. - Research and development

We will accumulate information and technological knowledge related to the ecosystem and promote related technological research and development. - Collaboration with society

We will endeavor to contribute to society through participation in regional environmental preservation activities and academic society/association activities.

Disclosures based on the recommendations of the TNFD

The Haseko Group, as a corporate group for housing to create great living, aims “to contribute to society by creating an optimal environment for cities and people.” We recognize that each of our businesses has impacts on the natural environment, while reaping various benefits from it. Therefore, we believe that we can never ignore the ongoing loss of biodiversity.

Given these conditions, with the belief that addressing biodiversity is an important management issue, the Haseko Group registered Haseko Technical Center as a Natural Symbiosis Site and OECM. We will continue to make disclosures in accordance with the recommendations of the TNFD, as well as monitor and appropriately deal with governmental measures and social trends, while aiming to realize a sustainable society and improve corporate value.

Governance

As a subordinate body under the committee, we also have the “Sustainability Promotion Conference” to engage in promoting and instilling CSR activities across the Group, including environmental initiatives such as decarbonization, energy and environmental technologies.

Role of Each Body

| Body | Role | Composition | Frequency of meetings | Secretariat |

|---|---|---|---|---|

| Sustainability Committee | Deliberates and decides matters on sustainability management at the management level | [Chairperson] President of Haseko Corporation [Members] Officers in charge of Haseko Corporation divisions and Haseko Group company presidents |

twice a year | Sustainability Promotion Department |

| Sustainability Promotion Conference | Deliberates and executes specific policies for sustainability management | [Members] Operating officer and Managers of Haseko Corporation and Haseko Group companies | three times a year |

Strategy

The Haseko Group evaluated its businesses in terms of nature-related dependencies, impacts, risks, and opportunities, in accordance with the TNFD’s recommended LEAP Approach. After identifying the scope of evaluation in the Scoping (identifying the targets for evaluation) phase, the Locate (identifying the interface with nature), Evaluate (evaluating dependencies and impacts), Assess (assessing risks and opportunities), and Prepare (considering countermeasures) phases were implemented.

- Identifying the scope of evaluation

(Scoping) - The Haseko Group identified the magnitude of potential dependencies and impacts on nature of all of its businesses. Based on the results, we selected the construction business as the target for evaluation. For the upstream supply chain, cement was selected as the target for evaluation out of main raw materials in the construction business.

- Identifying the interface with nature

(Locate) - We identified the interface with nature for the upstream supply chain. Cement suppliers were organized by area and we evaluated the state of nature in these areas.

- Evaluating dependencies and impacts

(Evaluate) - We identified the dependencies and impacts on nature across the entire supply chain in the construction business and evaluated their magnitude.

- Assessing risks and opportunities

(Assess) - We identified the nature-related risks and opportunities across the entire supply chain in the construction business and assessed their magnitude and possibility of arising.

- Preparing to respond and report

(Prepare) - We clarified countermeasures for the assessed risks and initiatives for the identified opportunities and prepared to disclose the information.

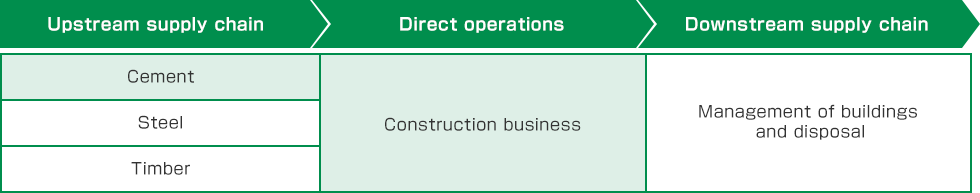

Defining the Scope of Evaluation

We selected the Construction-Related Business as the target for evaluation as it is the Haseko Group’s largest business among its main businesses and thought to have a high impact on nature.

To determine the scope of evaluation for the supply chain in the Construction-Related Business, we utilized ENCORE*, the TNFD’s recommended tool, and evaluated its businesses and procured materials across the entire supply chain that have significant connections to nature. For the upstream supply chain, we selected cement, steel, and timber as the targets for evaluation as the Haseko Group procures them in large volumes and they are included in the SBTs for Nature’s High Impact Commodity List.

Based on the evaluation, we selected direct operations and upstream supply chain as the targets for evaluation as they have high dependencies and impacts on nature. In addition, for the upstream supply chain, cement was selected as the evaluation target as it has high dependencies and impacts on nature and is procured in high volume.

*ENCORE: A tool for corporations across a range of sectors and industries that facilitates evaluation and identification of the levels of impacts and dependencies on nature in their business locations as well as locations where their partners procure raw materials.

The scope of evaluation

Volume of materials procured

Main construction materials(actual figures for FY2023)

Reinforcing steel 196,000t

Steel frame 32,000t

Freshly-mixed concrete 1,304,000㎥

Evaluation of Priority Locations

In this evaluation of priority locations, we clarified information on the locations of manufacturing plants for cement, the evaluation target selected, as well as those of mines of limestone, a main raw material for cement. And we evaluated the state of nature around these locations.

We procure all cement and limestone, a ram material of cement, domestically. Although limestone mines are located across Japan, many of the mines are located in northern Kyushu and Saitama Prefecture and thus cement production is concentrated in these regions.

Based on the distribution of domestic cement manufacturing plants and limestone mines, we evaluated the cement that we procure as shown below. We identified that certain limestone mines and cement manufacturing plants may be priorities for evaluation and countermeasures, in terms of conservation significance and ecosystem integrity.

| Conservation significance | Some limestone mines and cement suppliers may be located in close proximity to protected areas and key biodiversity areas (KBAs). |

|---|---|

| Ecosystem integrity | Some limestone mines and cement suppliers may be located in areas of high ecosystem integrity |

| Rapid decline in ecosystem integrity | Most limestone mines and cement suppliers are not located in areas where there could be a rapid decline in ecosystem integrity. |

| Physical water risks | Most limestone mines and cement suppliers are not located in areas of high water stress. |

| Importance for ecosystem services | It is unlikely that indigenous people or local communities exist in the vicinity of limestone mines and cement suppliers. |

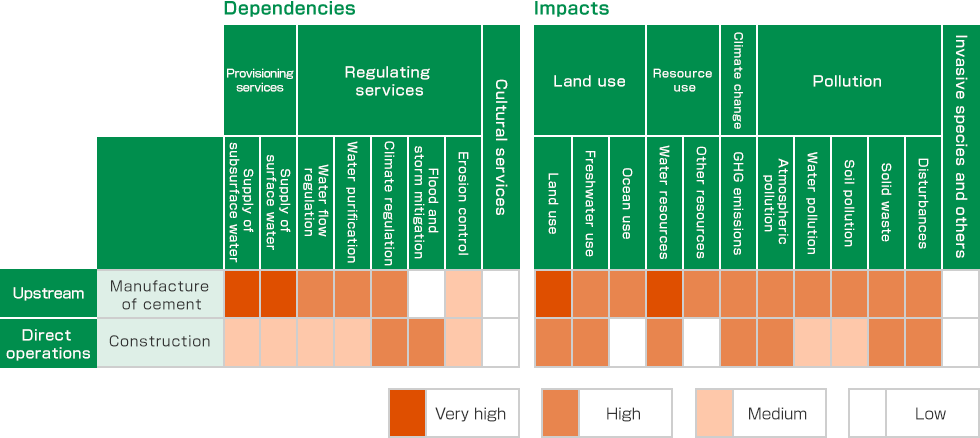

Evaluation of Dependencies and Impacts

In the Evaluate phase, we clarified how the Construction-Related Business depends and has impacts on nature through its supply chain.

Upstream cement manufacture showed high dependencies and impacts as a whole. Specifically, significant dependencies were identified in relation to changes in land use, use of water resources, and water supply.

The construction business, a directly-operated business, showed to have impacts on nature in terms of changes in land use, use of water resources, pollution, etc. Meanwhile, the business showed to depend on benefits from nature in terms of supply of water resources, water flow regulation, and climate regulation.

Levels of dependencies and impacts in upstream and direct operations (heatmap)

Outline of dependencies and impacts in the upstream and direct operations

| Primary impacts | ||

|---|---|---|

| Target | Procurement of raw materials (cement) | Construction |

| Land use |

|

|

| Resource use |

|

|

| Climate change |

|

|

| Pollution |

|

|

| Disturbances |

|

|

| Primary dependencies | ||

|---|---|---|

| Target | Procurement of raw materials (cement) | Construction |

| Provisioning services |

|

|

| Regulating services |

|

|

|

||

Assessing Risks and Opportunities

Based on the evaluation results of the Locate and Evaluate phases, we identified the nature-related risks and opportunities in the construction business and investigated their magnitude and possibility of arising.

With regard to risks, which have been partially evaluated as part of a climate change risk scenario analysis, we identified the likelihood that countermeasures will be required to ensure traceability for cement and sustainability of mining sites and that transitional risks will arise stemming from tighter regulations regarding matters such as land-use changes and pollution, in addition to that of physical risks of disruptions in procurement and delays in construction due to floods or droughts causing damage to suppliers or construction sites.

As for opportunities, we identified the opportunities including demand for environmentally friendly concrete, requests for creation of green areas and wooden buildings, acquisition of biodiversity certification, reduction of CO2 emissions during construction through measures such as use of environmentally friendly fuel, and construction of disaster-resilient condominiums.

For our material risks and opportunities, we will continue to implement the countermeasures we are currently taking and also consider undertaking additional measures. In this fiscal year, our evaluation targeted the construction business and cement, a procured material in the business, but in the future, we plan to implement evaluations and disclosures for our other businesses and procured materials.

| Category | Description of risks and opportunities | Magnitude | Possibility of arising |

Timeframe | |

|---|---|---|---|---|---|

| Upstream (cement) | Physical risks |

Unstable cement production due to water shortages, natural disasters, etc. | Medium | Medium | Medium-term |

| Transitional risks |

Higher costs of measures to ensure the traceability of cement and sustainability of mining sites | Medium | Medium | Medium-term | |

| Opportunities | Capturing demand for development and utilization of environmentally friendly concrete and raw materials that substitute for cement | Large | High | Medium-term | |

| Direct operations (construction business) |

Physical risks |

Delays in construction projects due to water shortages, natural disasters, etc. | Medium | High | Short-term |

| Lower levels of housing satisfaction among residents due to water shortages, natural disasters, climate change, etc. | Medium | High | Short-term | ||

| Transitional risks |

A decline in the number of projects due to tighter regulations on land-use changes | Medium | Medium | Medium-term | |

| Higher costs of measures to respond tighter regulations on environmental impacts during construction such as pollution, noise, and greenhouse gas emissions | Medium | High | Medium-term | ||

| Responding to tighter regulations on environmental impacts of use of buildings | Medium | Medium | Medium-term | ||

| Opportunities | Capturing demand and improving reputation by creating green areas, constructing wooden buildings, acquiring biodiversity certification, etc. | Large | High | Medium-term | |

| Reducing CO2 emissions at construction sites by using environmentally friendly fuel, electric forklifts, etc. | Large | High | Medium-term | ||

| Conservation activities in forests and our own facilities and development of greening technology through the activities | Medium | High | Medium-term | ||

| Capturing demand by constructing disaster-resilient condominiums | Large | High | Medium-term | ||

| Capturing demand by promoting energy-efficient buildings such as the ZEH-M business | Large | High | Medium-term | ||

Clarification of Countermeasures

We clarified countermeasures for the risks assessed and initiatives for opportunities as follows:

| Upstream (cement) |

|

| Direct operations (construction business) |

|

Impacts and Management of Risks

We sort out nature-related risks at related divisions across the Group and analyze their impacts on our businesses. The risks analyzed are deliberated by the Sustainability Committee and reported to the Board of Directors.

As a first step, we did not perform quantitative calculations regarding financial impact this time, but we qualitatively evaluated the chance of risks materializing, their timeframe, impact if they do materialize, and the state of current countermeasures, and categorized the impact as large, medium, and small.

In anticipation of a variety of risks, the Haseko Group endeavors to collect risk-related information and prepares preventive measures and appropriate countermeasures in advance against risks according to their magnitude and possibility of arising. Through these efforts, we aim to minimize the potential losses and to systematically cope with risk management centering on the Risk Management Department.

Specifically, the Haseko Group has set up a system in which respective sections of the Corporate Management Division coordinate with each other and check the status of business operations in accordance with the roles they are assigned, while the Internal Auditing Department conducts further checking. For the corporate approval system that serves as a record of decision-making for work implementation, we have introduced an electronic system which enables auditors and the Corporate Management Division to view and check the content at any time.

Furthermore, of the issues forwarded to the Board of Directors, the Management Council and the two operation councils (the Business Operation Council and Technology Operation Council), those involving many departments or requiring specialized knowledge are subject to sufficient verification in advance by the adequately established advisory meetings and committees. Periodical results reports are also mandatory for issues that require monitoring.

On top of these, the Haseko Group established the Risk Management Committee under the chairmanship of the President with the aim of strengthening the risk management system of the entire Group, and conducts cross-sectional collection of information, analysis, valuation and handling of risks in accordance with the internal rules on risk management.

Going forward, we will continue to strengthen the risk management system, with the aim of further enhancing risk management.

Metrics & Targets

The Group measures, discloses, and monitors actual results for the following metrics.

| Metrics | Quantity |

|---|---|

| Total quantity of pollutants released into soil by type | Zero environmental issues |

| Waste water emissions | Refer to ESG Data: “Water usage (thousand cubic meters) > Total effluents”*1 |

| Generation of waste and disposal | Refer to ESG Data: “Volume of waste generated and discharged,” “Volume of recycled waste,” and “Final amount of waste processed”*1 |

| Plastic pollution | Refer to Cyclical resource use: “Construction waste treatment status”*2 |

| Total quantity of atmospheric pollutants | Refer to ESG Data: “Quantities of hazardous substances and atmospheric pollutants”*1 |

| Total water intake and consumption from areas of water shortage | Refer to ESG Data: “Water usage (thousand cubic meters) > Total water intake”*1 |

| Amount of high-risk commodities procured | Refer to Flow of materials: Amount of resource injected for “Reinforcing steel,” “Steel frame,” and “Freshly-mixed concrete”*3 |

For targets and actual results, please use the following links.

Initiatives for Biodiversity

For more information on the promotion of biodiversity initiatives, click the link below.

- Related information

-

- Protecting the precious environment: Consideration for Biodiversity: Example: Creating verdant spaces that harmonize with the environment

- Constructing Biodiversity-Conscious Condominiums(Japanese Only)

- Press release: Haseko Technical Center registered in international database as first OECM in Japan(Japanese Only)

- Press release: Haseko Technical Center Certified as a Natural Symbiosis Site by the Ministry of the Environment(Japanese Only)

- Sustainability TOP

- Message from the Management

- Message from the Officer in Charge of Sustainability Promotion

- Haseko Group's Sustainability Management

- Climate Change Response

- The Digital Transformation Strategy of the Haseko Group

- D&I at the Haseko Group

- Creating attractive living spaces

- Building a company worth working at

- Protecting the precious environment

- Nurturing a culture of trust

- ESG Data and Disclosures

- External Evaluations and Awards

- Integrated Report

- Philosophy and Policies

- Special feature archives